As a leading supplier of powder coating line equipment, we understand that adopting the right technology is essential for achieving superior coating results. Customized powder coating systems, designed to suit the specific needs of each client—whether it's based on product material, size, production capacity, available space, or energy type—offer significant technological advantages that drive efficiency, quality, and long-term sustainability.

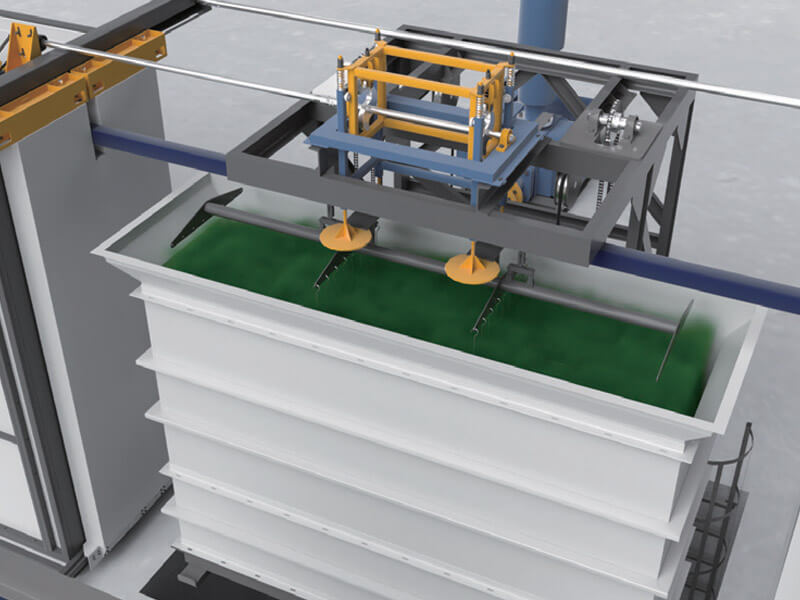

1. Advanced Precision and Control

Customized powder coating technology allows for the integration of advanced features tailored to the specific requirements of the coating process. This includes precision spray guns, adjustable settings for powder application, and automated systems for consistent coating thickness. The technology ensures uniform coating coverage, minimal overspray, and reduced material waste, delivering high-quality finishes even for complex or delicate products.

2. Energy Efficiency

One of the standout advantages of customized powder coating technology is its ability to optimize energy usage. Whether your facility relies on electric, gas, or hybrid systems, customized equipment can be designed to minimize energy consumption while maintaining optimal performance. Energy-efficient curing ovens, for example, reduce the time and cost associated with the curing process. Additionally, advanced control systems can regulate energy consumption based on real-time needs, improving sustainability and lowering operational costs.

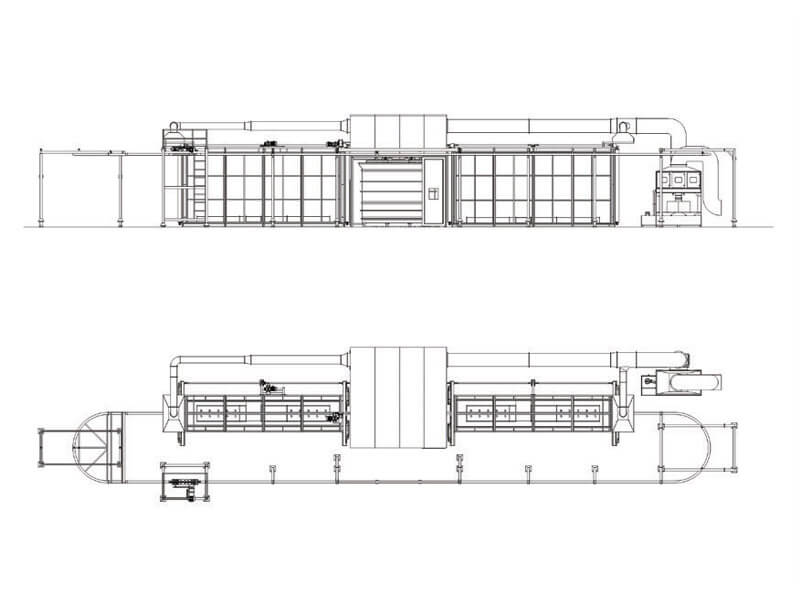

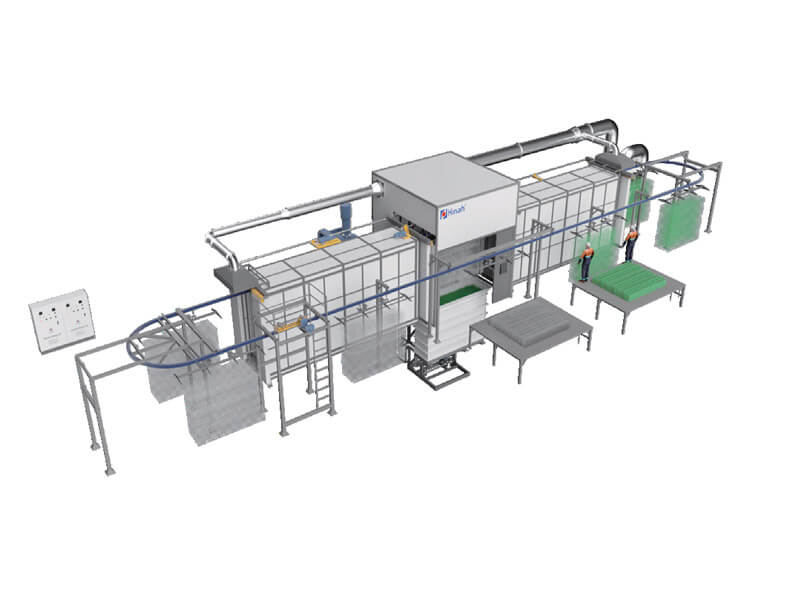

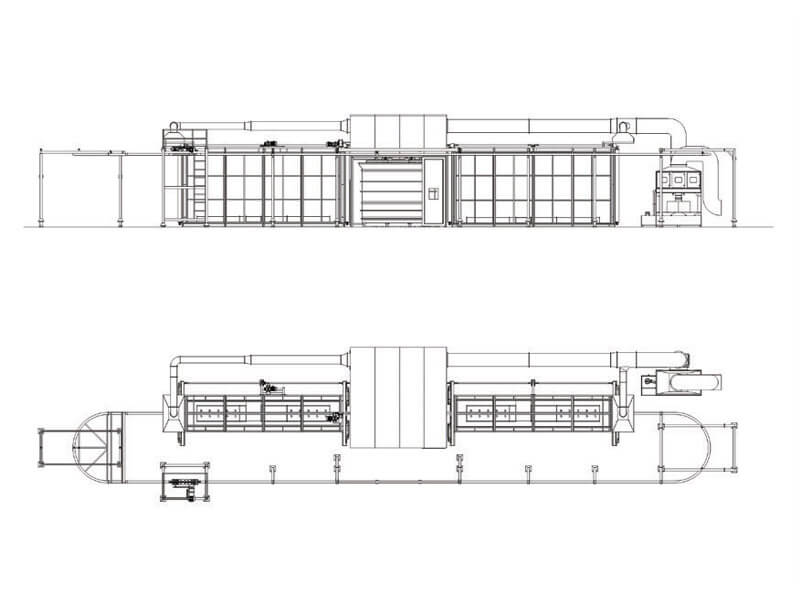

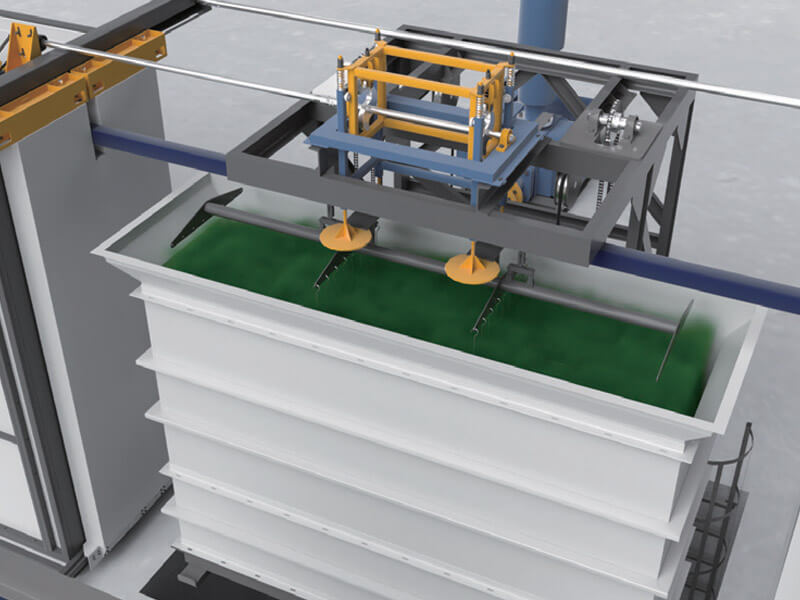

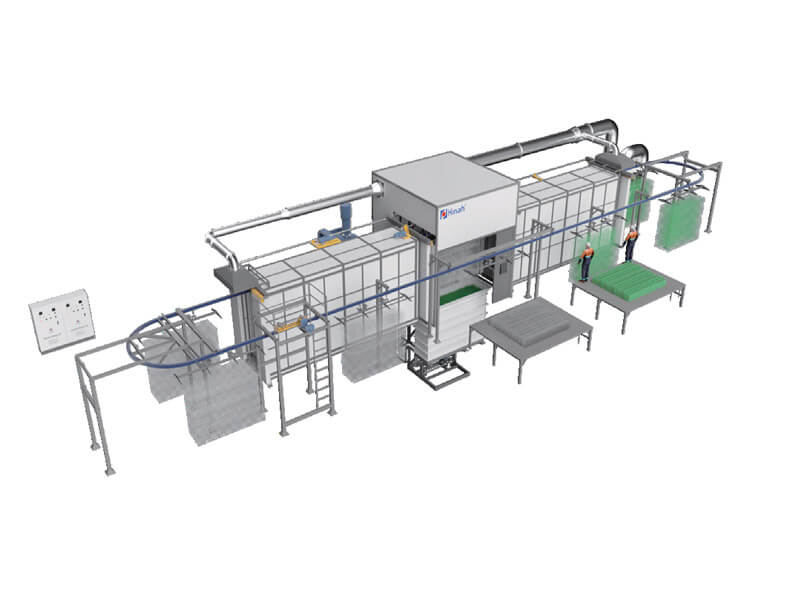

3. Enhanced Automation and Integration

Technology-driven automation in customized powder coating systems ensures higher throughput with minimal manual intervention. From automatic part loading/unloading to conveyor systems and curing processes, automation reduces labor costs, increases production rates, and minimizes human error. Moreover, these systems can be seamlessly integrated with existing production lines, allowing for smooth workflow without disrupting current operations.

4. Increased Flexibility

Customized systems allow for a wide range of adjustments based on product size, material, or production volume. This adaptability enables businesses to coat diverse products without compromising quality or efficiency. The technology is designed to handle various substrates and offer flexibility in production batches, from small to large quantities, providing a competitive edge in a fast-paced market.

5. Real-Time Monitoring and Data Analysis

Modern powder coating technology includes advanced monitoring systems that offer real-time data analysis of key parameters, such as coating thickness, curing temperature, and powder usage. These systems help ensure process consistency, identify potential issues early, and optimize operational performance. This data-driven approach supports decision-making and process improvement.

In conclusion, the technology behind customized powder coating equipment offers several advantages, including precise control, energy efficiency, advanced automation, flexibility, and real-time monitoring. By tailoring the technology to your specific needs, you can achieve superior coating results, improve efficiency, and maintain sustainability—all while reducing operational costs.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro