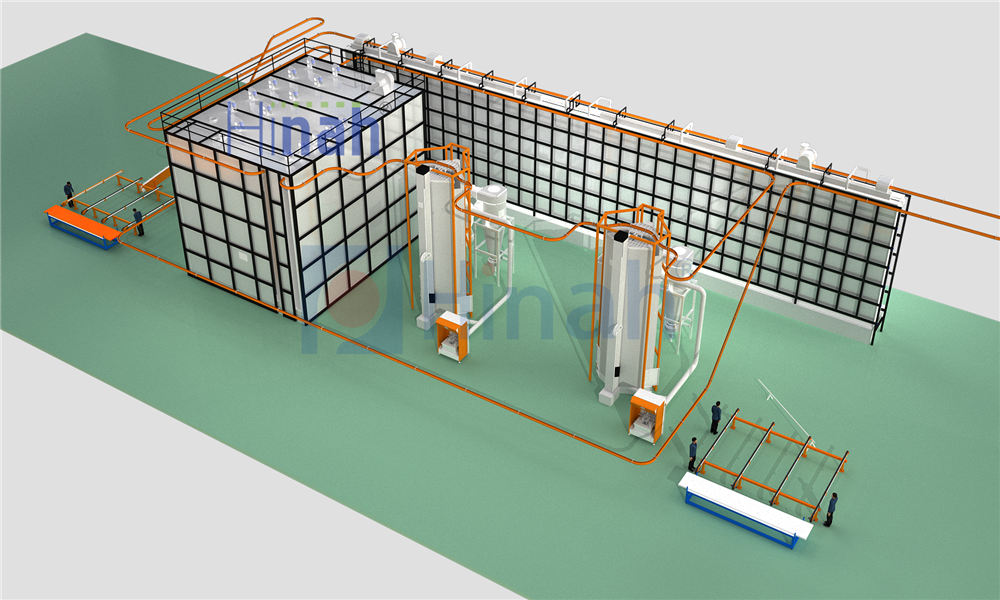

Vertical powder coating line offers several key advantages. Its vertical design allows for efficient space utilization and ensures even coating on long, vertically oriented aluminum profiles. The automated process improves coating consistency, reduces labor costs, and enhances productivity by minimizing human error.

With customizable features, the line can handle different profile sizes, colors, and finishes, meeting specific production requirements. Additionally, the system is energy-efficient and reduces powder waste, making it an environmentally friendly solution. The precise control over curing and coating thickness ensures high-quality, durable finishes, ideal for the aluminum industry.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)