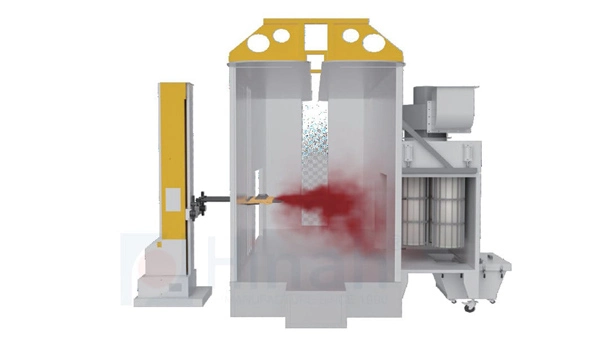

Powder coating spray pretreatment is a crucial process to ensure optimal adhesion and durability of the powder coating. It involves cleaning and preparing the surface of the substrate (such as metal) by removing contaminants like oil, grease, dirt, and rust. Common pretreatment methods include chemical cleaning, phosphate coating, or abrasive blasting. This step enhances the surface's ability to bond with the powder coating, resulting in a smooth and long-lasting finish. Proper pretreatment not only improves coating quality but also reduces the risk of defects, ensuring the coated product's performance in various applications.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)