As a supplier of powder coating line equipment, we recognize that the construction of the equipment plays a vital role in its performance, efficiency, and longevity. Customizing the construction of powder coating systems based on specific client requirements—such as product material, size, production capacity, available space, and energy sources—offers a range of advantages that can significantly enhance overall operations.

1. Optimized Structural Design

Customized construction ensures that every component of the powder coating line is designed to perfectly suit the size and shape of the products being coated. Whether the equipment is for small, intricate parts or large, heavy items, tailored construction guarantees that the system accommodates the exact specifications. This minimizes material waste, enhances handling efficiency, and ensures the smooth operation of the entire system.

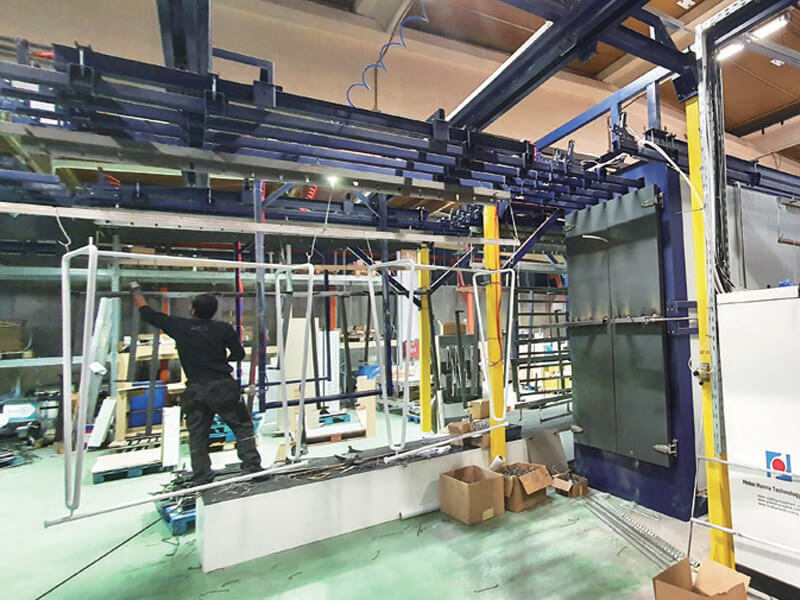

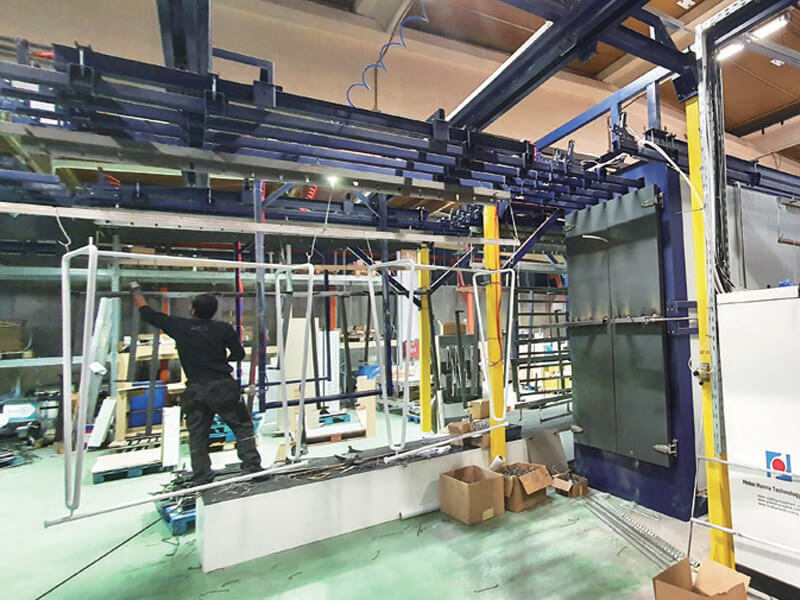

2. Space Efficiency

In many manufacturing environments, space is at a premium. A custom-built powder coating system is designed to fit within the available floor area, maximizing the use of space while avoiding unnecessary expansions. The equipment can be configured to take advantage of vertical space or compactly integrate within existing production lines, ensuring that the system doesn’t interfere with other operations and optimizing floor space utilization.

3. Enhanced Durability and Reliability

The construction quality of a customized system is optimized for the specific demands of the production environment. Heavy-duty materials, reinforced components, and specialized coatings are incorporated based on the type of products being coated, ensuring the system’s longevity. This reduces maintenance needs and downtime, improving overall reliability. A robust, purpose-built system is less prone to wear and tear, providing long-term value for the client.

4. Tailored to Energy Needs

Different manufacturing facilities may rely on different energy sources. Custom construction allows for the integration of energy-efficient systems, whether it’s electric, gas, or hybrid solutions. The design can be optimized to match the client’s specific energy preferences, minimizing operating costs while improving overall system efficiency.

5. Better Workflow Integration

Custom construction ensures that the powder coating equipment integrates smoothly into the client’s existing production line. The system can be designed with specific material handling capabilities, such as conveyors or automated loading/unloading, reducing labor costs and optimizing workflow efficiency.

In conclusion, customized construction of powder coating equipment offers substantial advantages, including optimized design for product handling, efficient use of space, enhanced durability, energy optimization, and seamless workflow integration. By providing a tailored solution, we help clients maximize performance, minimize costs, and achieve superior results.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro