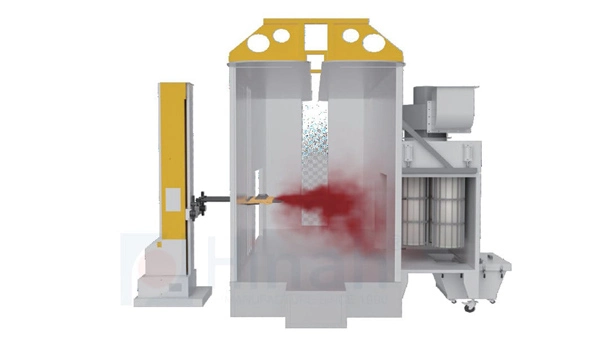

Powder Coating Booth with a Large Cyclone Recovery System is designed to enhance powder coating efficiency and minimize material waste. This system uses a high-powered cyclone to capture oversprayed powder and separate it from the air stream, ensuring the powder is collected and can be reused. The booth is equipped with efficient filtration systems to maintain air quality and prevent contamination. Ideal for high-volume operations, the large cyclone recovery system allows for continuous production while reducing material costs. It is commonly used in industries like automotive and metal fabrication, where consistent coating quality and waste reduction are essential.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)

.jpg)