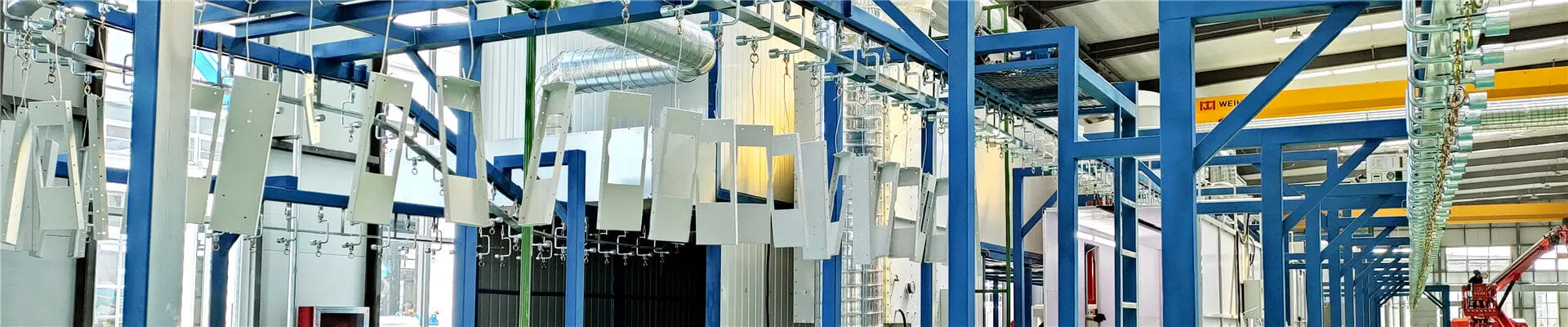

Powder coating robots are automated systems designed to apply a uniform layer of powder to a workpiece in a controlled and efficient manner. These robots are equipped with spray guns that use electrostatic charge to attract powder particles to the surface of the item. They offer precise control over coating thickness, consistency, and coverage, making them ideal for high-volume production environments. Powder coating robots are commonly used in industries such as automotive, appliance manufacturing, and metal fabrication, improving productivity, reducing labor costs, and ensuring high-quality finishes with minimal waste. They are often integrated into conveyor systems for continuous operation.

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

.webp)

.webp)

.webp)

.webp)

.webp)

.jpg)

.jpg)

.jpg)