Powder coating equipment offers superior durability, resistance to wear, and a more even finish compared to traditional liquid coatings. It also reduces environmental impact by eliminating solvents, making it more eco-friendly and cost-effective in the long run.

-

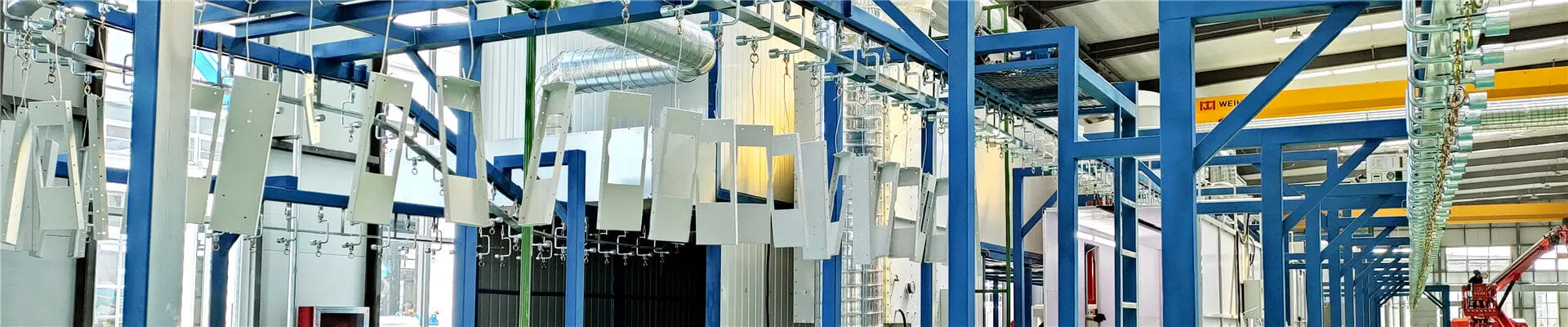

Powder Coating Line

- Automatic Powder Coating Line

- Manual Powder Coating Line

- Powder Dip Coating Line

- Vertical Powder Coating Line

- Horizontal Powder Coating Line

- Small Powder Coating Line

- Aluminium Powder Coating Plant

- Almirah Powder Coating Plant

- Conveyorised Powder Coating Plant

- Industrial Powder Coating Systems

- Powder Coating Equipment

- Painting Line System

-

E-Coating Line

- Monorail E-Coating Line

- Gantry Stepping E-Coating Line

- Accumulation Conveyor E-Coating Line

- Trolley Hoists E-Coating Line

- E-coating System Accessories

- Aluminum Products E-Coating Line

- Automotive Body E-Coating Line

- Automotive Parts E-Coating Line

- Small Electric Cars E-Coating Line

- Power Moto Tricycle E-Coating Line

- Electric Appliances E-Coating Line

- Castings E-Coating Line

- Stainless Steel Products E-Coating Line

- Support

- About Us

-

Get a Quote

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro