In 1990, starting from a small military equipment maintenance shop, the company gradually expanded its operations, focusing on high-quality service and innovative solutions in equipment care and repair.

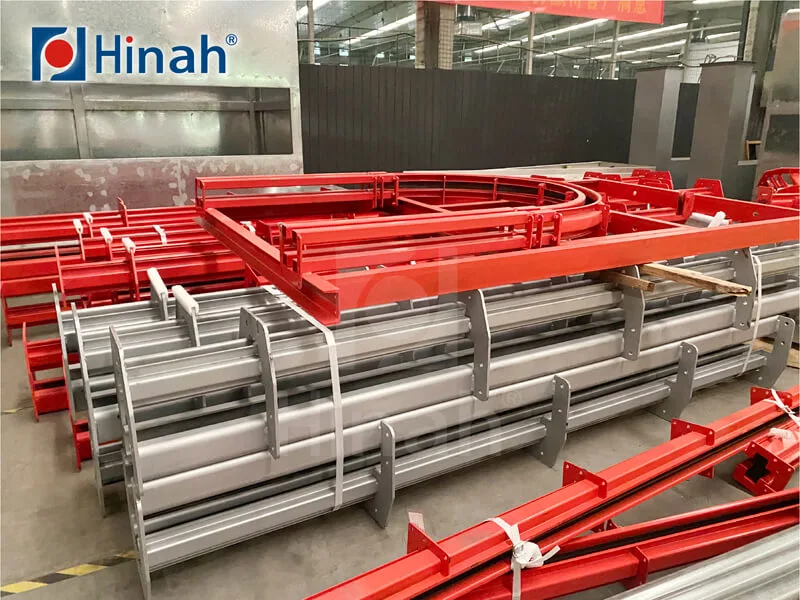

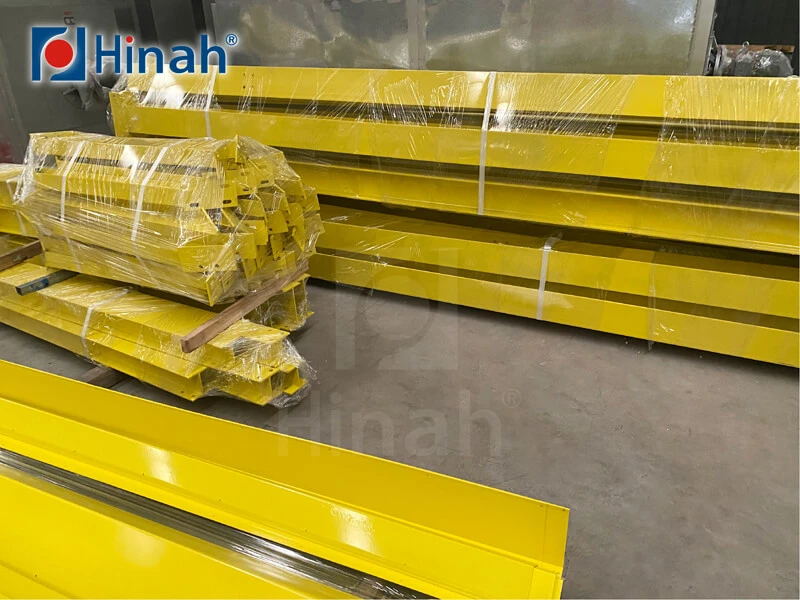

Hanna Technology is a company with many years of experience in developing and selling powder coating equipment and wet painting line, from simple manual machine to fully automatic line, we are able to provide our customers with perfect cost-effective, reasonable and advanced solutions. The company has passed CE, ISO 9001 and other international quality system certifications, and the products we produce and sell have grown to dozens of series. With Hanna's proud technology, you will have your best metal surface treatment solution.

Our goal is to give our customers a strong competitive edge. Tailor-made design solutions with the best energy efficiency performance, using practice and experience to optimize the design details of the equipment to provide the most reliable and efficient equipment and systems. With over 30 years of experience in industrial coating systems including powder coating line, liquid painting line, dip coating line, E-coat line, painting line robot, power and free conveyor line, we are your first choice for intelligent surface treatment equipment in China.

Hanna Technology keeps impressive record on serving customers like small manufacturers, government projects and global cooperation. Relying on 30 years of production experience and technology, we develop and manufacture custom-design solutions to provide durable, long-lasting and cost-effective equipment. Many projects have been completed all over the world, including China; North America (USA, Canada, Dominica, Mexico); Europe (UK, Ireland, Russia, Bulgaria, Cyprus, Croatia); Australia (Australia, New Zealand); Middle East (Qatar, Saudi Arabia, Egypt); Asia (Thailand, Philippines); South America (Colombia, Chile, Argentina); Africa (Morocco, Nigeria, Algeria, Kenya, South Africa), etc.

Hinah designs, engineers, manufactures, and installs a complete e-coating system for your needs.

We use the most reliable technology to tailor the system to your needs. It matches your capacity and needs, completes your tasks efficiently, and gives you a strong competitive edge.

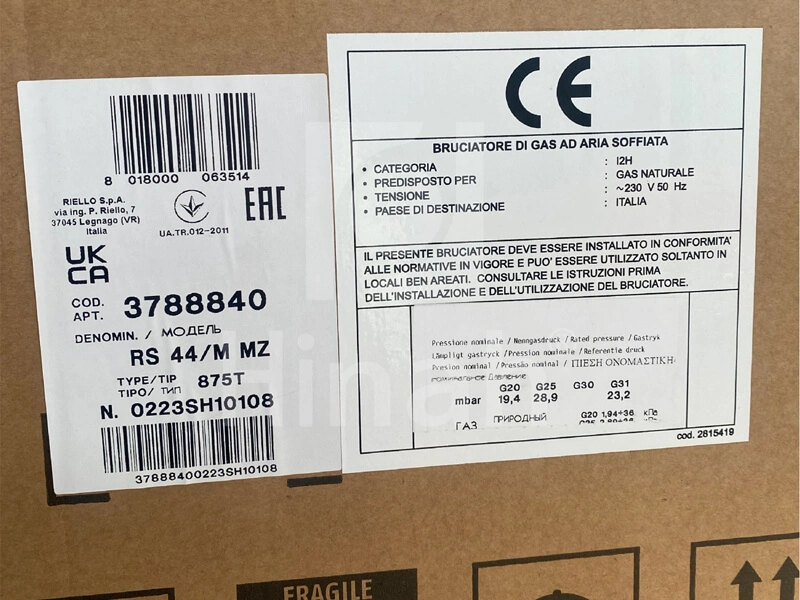

Leading technology and equipment to ensure a high-quality coating finish. Enhanced oven technology, advanced electrical systems, and precise temperature control systems ensure more efficient, reliable, and durable e-coating systems and equipment.

Our philosophy is to work around our clients and we do this with a full chain of input and support. From initial requirements and design, through production, shipment, installation, commissioning, and training, until your system is ready for production.

Ensure the powder used is consistent in particle size and chemical composition to guarantee uniform coating results.

Regularly calibrate spray guns to maintain optimal electrostatic charge, improving coating adhesion and finish quality.

Monitor temperature and humidity in the spray booth to prevent powder adhesion issues and ensure consistent coating thickness.

Implement routine maintenance for all equipment, including ovens and conveyors, to avoid downtime and maintain production efficiency.

In 1990, starting from a small military equipment maintenance shop, the company gradually expanded its operations, focusing on high-quality service and innovative solutions in equipment care and repair.

In 2000, the company established a surface treatment equipment factory, focusing on the design and manufacturing of advanced equipment for various industrial applications, enhancing production efficiency and coating quality.

By 2010, the company successfully completed over 300 projects in the domestic market, earning a strong reputation for delivering reliable, high-quality surface treatment and coating solutions across various industries.

In 2014, the company established an Export Department to expand its reach internationally, promoting its innovative surface treatment equipment and solutions to global markets while ensuring high-quality service and support.

In 2018, the company applied for over 80 authorized patents in the metal surface treatment industry, demonstrating its commitment to innovation, advanced technology, and leadership in developing cutting-edge solutions.

By 2024, the company had expanded its export reach to over 30 countries, successfully completing more than 1,000 projects, and establishing a strong global presence in the surface treatment industry.